Safety Data Sheet Guide

- Aug 13, 2025

- 5 min read

Updated: Aug 25, 2025

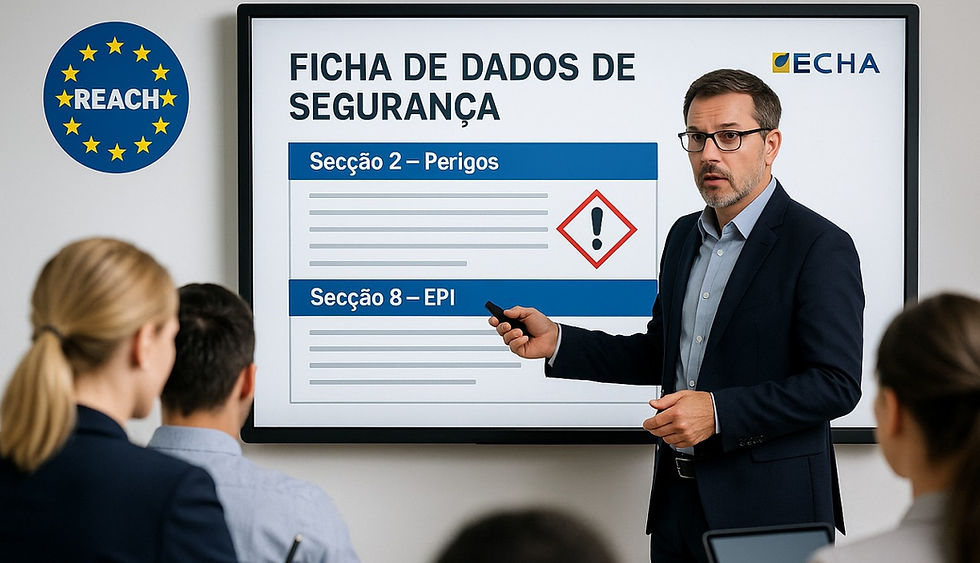

The daily management of Safety Data Sheets (SDS) is a demanding and resource-intensive task within any company. It's a deeply technical topic that requires constant attention to changes in current legislation and corresponding adjustments to company processes.

This document aims to summarize what an SDS is and add some suggestions and precautions to take in its daily management.

Introduction to the Safety Data Sheet (SDS)

Safety data sheet management is the backbone of chemical product safety, and its importance is vital. Safety data sheets are the primary source of information for employers and workers, outlining the hazards of chemicals and the risks they pose to people and the environment, as well as measures to control these risks. Safety data sheets are essential sources of information for properly managing health and safety in the workplace.

However, the SDS alone is not sufficient. The SDS itself doesn't take into account your specific location, task, or how you use the product. Therefore, it's important to create a chemical risk assessment that takes these additional requirements into account.

Safety data sheets are essential documents in a standard format that are used to inform all workers and safety personnel about how chemical substances and mixtures of substances can be handled, used, stored, disposed of, and any emergency measures necessary in the event of an accident or incident.

Safety data sheets (SDSs), sometimes referred to by their former name as material safety data sheets (MSDSs), have had many formats over the years. Since the introduction of the GHS Regulations, a new structured, unified, and standardized approach to ensuring the safe use of chemicals has been introduced globally. While not all countries worldwide have yet adopted the GHS Regulations, since June 1, 2015, in Europe, all new SDSs compiled must conform to the new SDS format.

Safety data sheets are divided into 16 sections and additional subsections. In this guide, we will highlight the main elements of each section and explore their importance. It is important that all employees have read the SDSs for all chemicals they work with and have the knowledge to understand them. Typically, manufacturers/suppliers will provide SDSs with the product, either electronically or in hard copy. If they do not, it is up to the company/chemical user to contact the manufacturer and request a safety data sheet or find a reputable supplier who provides an SDS.

Before bringing the product to the site, review the hazards and determine its suitability. In other words, don't bring a product to the site if safer alternatives exist. Having a safety data sheet isn't enough; you must have the relevant safety data sheet for your geographic region.

According to European legislation, a compliant SDS must contain the following:

Sixteen sections

Classification and labeling according to GHS/CLP

Language of the market where the product is being marketed/where it will be used

Legislation on Safety Data Sheets (SDS)

Safety data sheets must be prepared in accordance with the REACH Regulation (Regulation (EC) No. 1907/2006) and the CLP Regulations (Regulation (EC) No. 1272/2008). These regulations set out the requirements for product classification and the format of the SDS.

Article 31 of REACH requires a chemical supplier (manufacturer, importer, downstream user, distributor) to provide their customer with a compliant SDS if the chemical they supply is hazardous. In some cases, SDSs must be provided whenever the customer requests them for non-hazardous chemicals and

that meet specific criteria as defined in the regulations.

Annex II of the REACH Regulation (EC) No. 1907/2006 has always defined the requirements for the preparation of an SDS since its introduction in 2007. In 2015, Annex II was revised by Regulation (EC) No. 2015/830 to take into account changes in the CLP Regulation and the 5th edition of the United Nations Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

According to REACH regulations in Europe, safety data sheets must be updated or reissued in the following cases:

New product information is added that may alter the chemical risk or hazard, such as a new classification. In this case, an updated SDS must be issued.

If an ECHA authorisation has been granted or refused.

Or if a restriction has been imposed by ECHA.

Understanding the SDS (Safety Data Sheet)

Most companies that purchase/use chemicals understand the legal requirements for obtaining and maintaining a safety data sheet. However, many companies don't understand what to do with the information provided in the SDS they obtain. All data provided is created with the goal of ensuring the protection of all chemical users.

The safety data sheet, according to the REACH guidelines, must contain the following 16 headings. The most important sections are Sections 1, 2, 3, 4, 7, 8, and 15:

Section 1: Identification of the substance/mixture and of the company/undertaking

Includes supplier contact details (product name, company name, address, emergency phone number)

Section 2: Hazard Identification

Provides an overview of the physical and health risks associated with the use of the chemical. Includes:

Hazard classification

Word of warning

Pictograms

Hazard Statement

Precautionary statement

Description of any hazards not otherwise classified

Additional requirements according to legislation

Section 3: Composition/information on ingredients

Includes approximate formula, molecular weight, concentration and CAS Number.

Section 4: First aid measures

Indicates what to do in case of a dangerous situation.

Section 5: Firefighting measures

Suitable protective equipment and extinguishing methods.

Section 6: Measures in case of accidental release

Containment, cleaning and exposure prevention practices.

Section 7: Handling and storage

Tips for safe storage and use.

Section 8: Exposure controls/personal protection

IInformation on PPE (glasses, gloves, etc.).

Section 9: Physicochemical properties

Description of the properties of the substance.

Section 10: Stability and Reactivity

Dangerous reactions, chemical stability and more.

Section 11: Toxicological information

Routes of exposure, symptoms, toxicity, acute and chronic effects.

Section 12: Ecological information

Environmental impact of the chemical.

Section 13: Disposal Considerations

How to dispose of and treat waste.

Section 14: Transport information

Classification and standards for transportation

Section 15: Regulatory information

Legislation applicable to the substance.

Section 16: Other Information

Other relevant data, reviews, training, etc.

Chemical Classification

How do we know which chemicals are classified as hazardous and which are not? This information comes from the classification system.

Since 2015, the CPL/CHIP system has been replaced by the CLP Regulation (part of the GHS). The orange square symbols have been replaced by diamond-shaped pictograms with a red border. If the product is classified as hazardous, the corresponding pictogram will appear in section 2.

SDS Checklist

✅ Check that the language and legislation are correct for your market.

✅ Confirm that it is dated and has details of the revisions.

✅ Archive current and past versions (paper or digital).

✅ Prioritize sections 1, 2, 3, 8, 9, 14.

✅ Check that the label corresponds to sections 1 and 2 of the SDS.

✅ Request a new version from the supplier if necessary.

✅ Use the SDS as a basis for risk assessments, PPE definition, and emergency response.

✅ Ensure access and training of employees on the SDS.

✅ Periodically review the SDS to ensure updates.

Comments